New Touchscreen Controller.

The RGS provides the greatest amount of accuracy and control available, which can reduce color usage and lower costs. The RGS is easy to set up and use. Calibration is not required. Our gravimetric system makes automatic metering adjustments as needed. Color change is quick and easy. The RGS can use 5 gallon pails, 30 gallon drums, or totes.

Zero Waste, Zero Landfill.

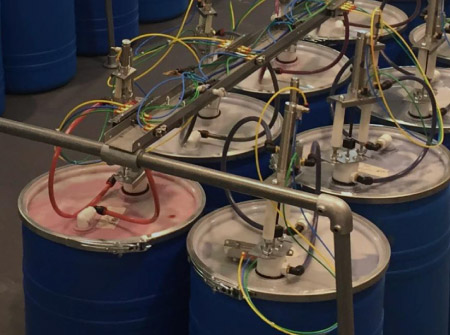

Every container delivered to your facility has its own pump, installed permanently in the drum or pail (Pump-In-A-Pail®). The containers are sealed and never need to be opened. You can send back the empty containers through our Return For Refill™ program, which will save you money and help the environment.Pump-In-A-Dru® (PIAD) is proven technology, in use by Riverdale for more than 10 years

Made to Last.

Each color has its own tube. To minimize color loss, delivery tubes are reusable, durable. and long lasting. Equipped with quick change connectors, color changes are easy and clean. Delivery tubes are sealed with shutoffs at both ends to eliminate dripping.

Custom Fit.

Custom made plates fit your machine to properly meter color into your process. Quick change connectors keep your color changes simple and clean. Now sealed to eliminate the dripping common with other designs.

Wide Throughput Range.

Pre-Mixers automatically and continuously provide thorough mixing of resin, regrind and additives as they enter the throat of the process machine. Our pre-mixers are customized to fit your processing machine and have various throughput ranges to meet your requirements. Each of our pre-mixers accept Riverdale Global's quick mount, patented liquid nozzle for precise liquid dose location.

Options to Optimize.

For applications with maximized shot sizes or limited screw/barrel mix capabilities, Riverdale Global offers customized mixing nozzles and pre-mixers. In addition to optimized mixing, our nozzle offering can also incorporate melt filters to protect valuable hot runner systems from the risk of tramp metal contamination.

Strong Steel Support.

Our spacer frames are made from 1/4" steel and can support the weight of a hopper and loader, so they can be mounted directly over the feed throat. Color is metered in by a removable nozzle. Inside the frame, a canopy directs resin to either side of the nozzle to help prevent color and resin clumping together. The spacer / nozzle option is a good solution in situations where a slide gate prevents us from metering into the throat directly over the screw. By using a removable color nozzle, this is also a good option if you frequently change from using color to running natural resin.

Saves Time and Labor.

Refill options minimize press downtime caused by material handling, or changing out empty color containers. Built in features on our RGS controller automatically signal a refill pump to transfer material from a local or remote container to top off the color supply to the pail or drum located on the RGS platform. This option is good for presses that run extended production using a single color.

The ripple of change.