Innovation at your finger tips.

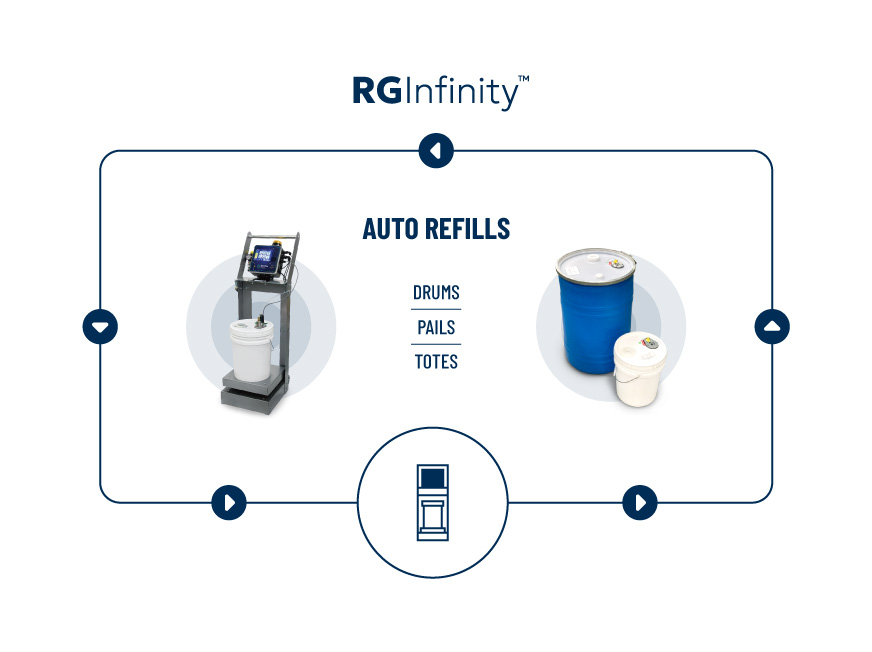

We have developed a material handling system, RGInfinity™, that automatically refills one or more liquid color drums during the molding or extrusion process.

Our RGInfinity™ auto-refill system.

We can offer custom solutions for color metering and multiple machine processes that would otherwise be unavailable.

Efficient

Eliminates need to replace drums when empty by refilling them from a large central container, or "tote."

Custom

Serves one machine or can be configured to refill multiple machines running the same color.

Clean

Keeps liquid color sealed off from the workplace through sealed connections from tote to delivery tubes to drums to metering tubes.

How it works.

Each drum is mounted on a Riverdale Gravimetric Stand (RGS), which monitors the weight of color in the drum and signals a pump valve on the tote when the drum is nearly empty and again when it is full. This prevents uncolored products.

When the central container needs to be replaced with a full one, the sealed connectors enable a quick changeover.

Containers are available in various shapes and sizes. Common container sizes to refill are 5 gallon pail, 30 gallon drum and 275 gallon IBC tote!

How it helps your process.

Eliminates downtime and labor required to:

- Switch drums

- Monitor color levels

- Transport and prepare replacement drums

- Wait until on-line drums are ready for replacement.

Reduces off-specification products with little or no color.

The ripple of change.